Innovation

We believe in continuous training of our team and are committed to developing innovative solutions in the research and development lab.

Specialisation

We design and manufacture five different product divisions to offer a wide variety of items designed down to the smallest detail.

Internationalisation

We take our Made in Italy production and quality all over the world thanks to a dense network of foreign subsidiaries and partnerships.

The experience of the past, the people of the present and the innovation of the future.

A leading manufacturer of fluid and compressed air components since 1976.

Da oltre quarant’anni siamo specializzati nella produzione di raccordi, valvole, elettrovalvole, attuatori e giunti automatici per fluidi e aria compressa, offrendo ai nostri clienti 5 differenti linee di prodotto.

Thanks to our experience and constant innovative spirit, we position ourselves as an industry leader in various areas of industrial automation, proposing customised solutions according to specific market requirements, in compliance with the highest standards of quality, design and safety..

The entire production is made in Italy and thanks to an extensive network of distributors we make our products available worldwide.

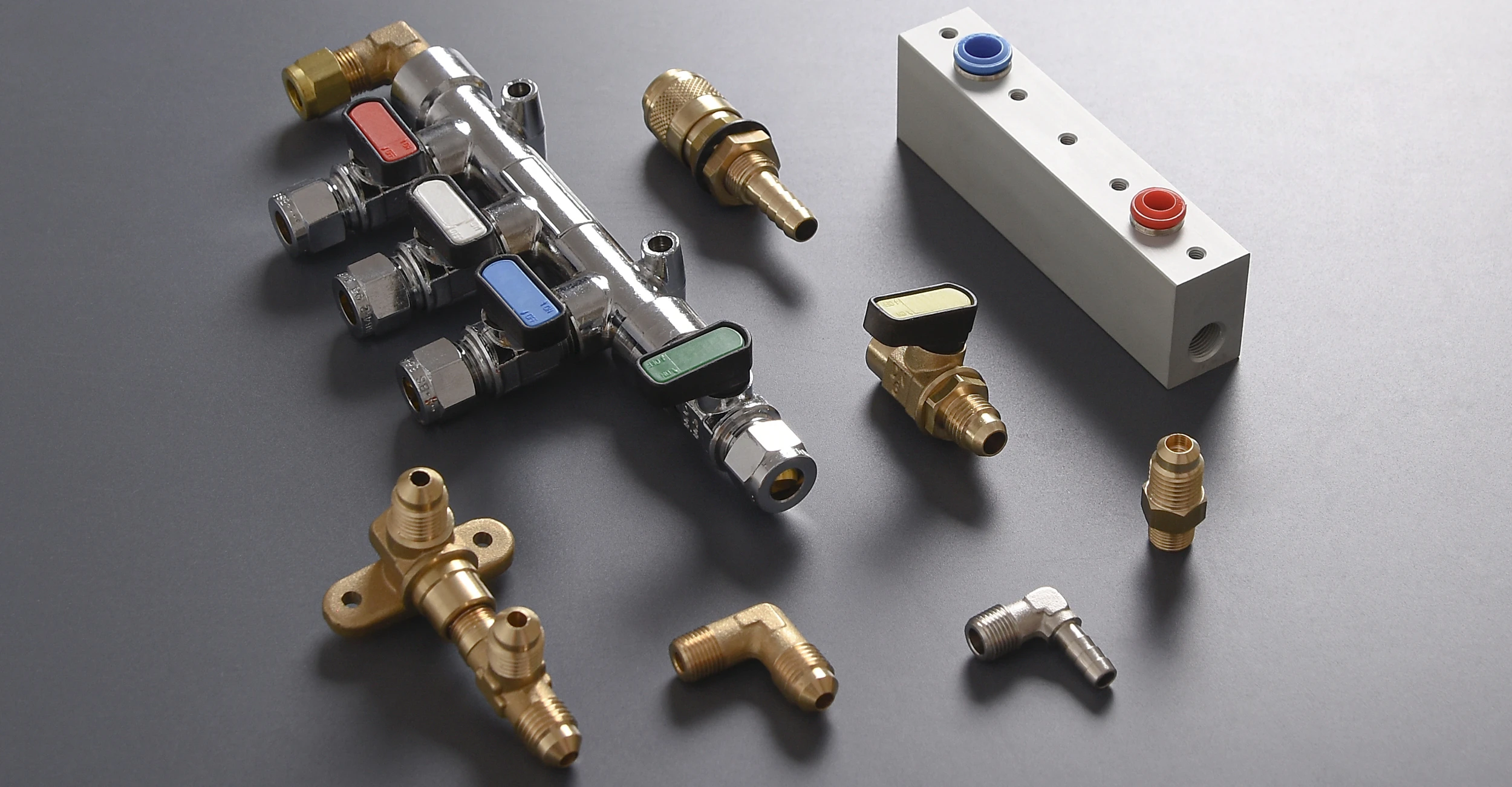

FIVE PRODUCT DIVISIONS

What distinguishes us from our competitors is our specialisation and the ability to offer the market five different product lines: Connections, quick-connect couplings, automation components with valves, actuators, FRLs and handling, Fluidity: solenoid valves for all types of fluid, and Infinity: a system for the distribution of compressed air, inert gases and vacuum.

Automatic, compression and function fittings, adapters, ball valves and hoses for fluids and compressed air.

Valves, pneumatic actuators, electric actuators and FRLs for compressed air treatment.

Automatic plug-in couplings and blow guns.

Infinity line for controlling compressed air, inert gases and vacuum.

Fluidity line for the distribution of liquid and gaseous fluids.

We are an international company and export our brand to more than 100 countries around the world.

We have established a network of 9 subsidiaries that allow us to be close to our customers and make all our products easily available. From the USA to Spain, from Switzerland to Brazil, from France to Colombia, from Germany to China and Russia.

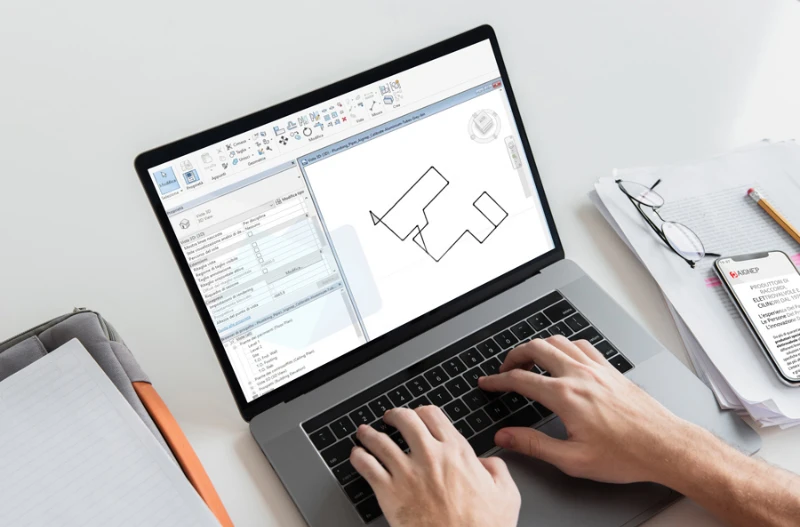

Within the 4.0 industry we have implemented each processing step with state-of-the-art machinery up to the final stage where the automated warehouse allows us to speed up delivery times. Furthermore, with the Aignep Scan app it is possible to send orders by scanning QR or barcodes directly from Aignep packages or pre-printed labels.

We manufacture made-to-measure products. A meticulous process where dialogue with the customer becomes fundamental at all stages of the production process: from the definition of the model to the realisation of the product. Our team of engineers is able to satisfy any request and supports the customer in defining the materials and type of product most in line with his needs.

The fast track to all information dedicated to Aignep customers.

The mobile app with which you can manage your warehouse and send your orders quickly and easily.

The application can calculate the correct pipe size to be used for a given project as it takes into account system length, air consumption and pressure drop.

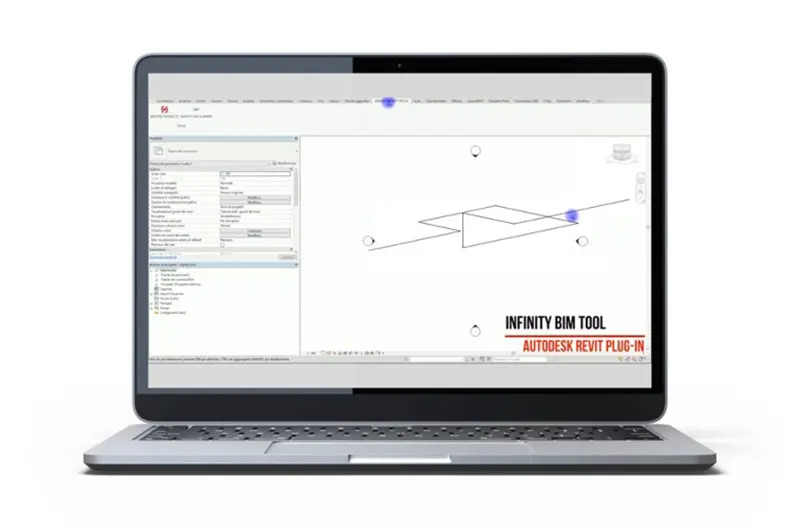

BIM, BUILDING INFORMATION MODELING is a digital building information system, consisting of a 3D model of the building and integrated with physical, performance and functional data for the realisation of an INFINITY project.

The Aignep plug-in for the REVIT programme is an extension made available to users, with which they will be able to connect in real time to the Infinity section of our site, directly from the REVIT software interface. In this way, the search for a BIM object will be immediate.

The Bugatti Group operates in diverse and complementary sectors:

from automation and solutions for fluid and compressed air technology to machine tools, from the design and construction of moulds for plastics and die-casting to the production of aluminium alloy and zamak die-cast components, from table and kitchenware to outdoor lighting systems and the production of energy from renewable and environmentally sustainable sources.