Innovate to create new value and future opportunities for our customers, achieving the best cost-benefit ratio for the total benefit of the customer.

Using technology in the service of people, improving the quality of life and environmental impact within production facilities, devoting the utmost attention to energy conservation.

Founded in 1958, the Picchi company is one of the Italian companies with the greatest tradition in the construction of Transfer Machines and CNC Machining Centers.

The company is an integral part of the Bugatti Group, of which it is the technical and technological Advisor, and from which it draws impetus for its own development.

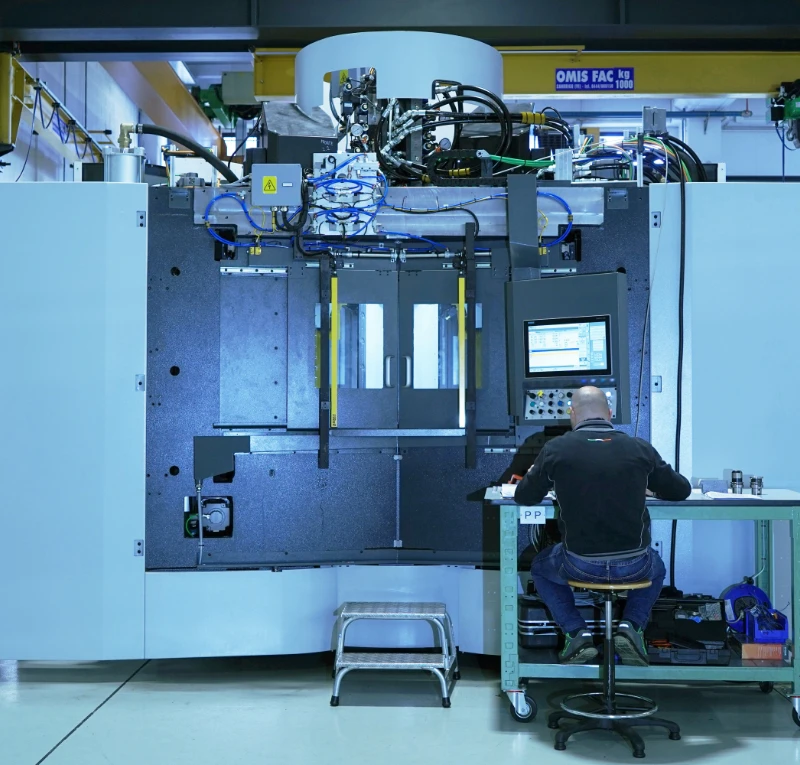

In the modern and functional headquarters, the most advanced technologies are used to guarantee the final quality of the products, and the sales network, present in the most advanced markets, has now consolidated an export share of around 70%.

We offer unique technical solutions for a development that pays attention to the overall manufacturing process and not just the machine, this allows us to achieve maximum economic yield while maintaining the correct "cost-quality" ratio.

Our approach is unique in the industry, we feel that we are first users ourselves, which allows us to seek the best solution for the end customer.

We always pay attention to environmental protection, in fact we are able to reduce the energy consumption of our products, ensuring the well-being and protection of operators.

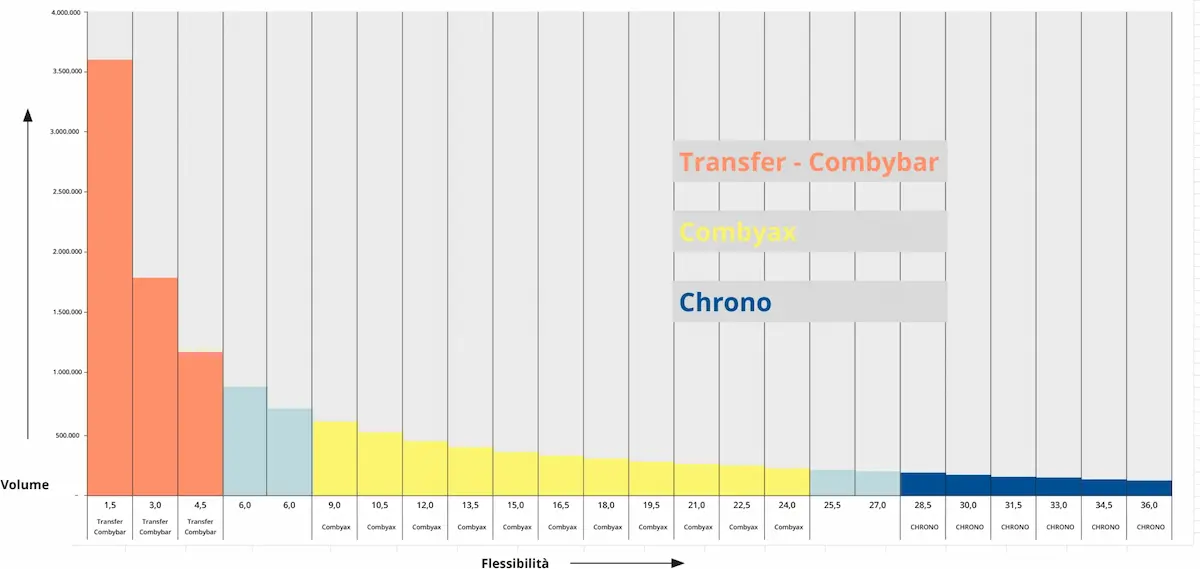

We design and offer our Machines and Automation with different solutions:

Thanks to our unique solutions, we are able to reduce tool consumption by 30% to 50%, resulting in high efficiency of both the machine and the overall system, thus reducing maintenance interventions.

All this while always having energy consumption at heart, in fact we equip our Machines with an energy recovery system. In particular, the motors, during deceleration, generate energy, which is subsequently recovered by a specially designed system, and reused when the motors need it during re-acceleration.

Our Company has always paid special attention to Service activities in order to achieve maximum Customer satisfaction through fast and punctual service supported by dedicated and experienced staff and complete availability of spare parts, even for machines installed many years ago.

To increase the effectiveness of our Service, we have at our disposal a software solution based on VR viewer, smartphones, tablets and PCs that enables information sharing between on-site operators and our support departments.

We can, therefore, assist users in performing difficult tasks and maintenance management by having, these, real-time data available, assisted remotely by our experts.

a - 4-axis multispindle chrono machining center

b - 5-axis multispindle chrono machining center

c - multispindle chrono machining center for integrated turning machining

d - extraordinary combyax flexibility

e - high performance, low maintenance transfer

f - ball diamond cutters

g - multi-spindle cnc, flexible non-rotating combybar feed.

The Bugatti Group operates in diverse and complementary sectors:

from automation and solutions for fluid and compressed air technology to machine tools, from the design and construction of moulds for plastics and die-casting to the production of aluminium alloy and zamak die-cast components, from table and kitchenware to outdoor lighting systems and the production of energy from renewable and environmentally sustainable sources.